Industrial Flour Sifter Manufacturers: Essential Tools and Top Providers for Quality Assurance

Industrial flour sifters are indispensable for businesses in food processing, especially bakeries and commercial kitchens where consistency, purity, and product quality are essential. A high-quality flour sifter not only refines flour by removing lumps and impurities but also helps to ensure that the texture and density meet industry standards. When choosing an industrial flour sifter, it’s essential to know which manufacturers provide the most reliable and effective equipment. This article explores the benefits of industrial flour sifters, the key features to consider, and the top manufacturers trusted by businesses worldwide.

The Role of Industrial Flour Sifters in Food Processing

Industrial flour sifters play a crucial role in refining and preparing flour for large-scale production. By sifting out unwanted particles, clumps, and potential contaminants, these machines ensure that only the finest, most uniform flour is used in production. In commercial baking and food manufacturing, flour sifters contribute to:

- Improved Product Consistency: Sifted flour mixes more uniformly with other ingredients, enhancing the texture and consistency of the final product.

- Quality Assurance: Removing impurities helps maintain product quality, ensuring each batch meets regulatory and customer standards.

- Production Efficiency: Automated sifters reduce labor requirements, improve processing speed, and handle large quantities of flour effortlessly.

This makes industrial sifters essential for bakeries, food processing plants, and any business that requires high-quality, contaminant-free flour.

Industrial flour sifter manufacturers focus on producing sifters that are efficient, durable, and capable of handling large volumes of flour with precision. To ensure the highest quality, industrial flour sifters are built with robust materials like stainless steel and are often designed with features such as multiple mesh screens, vibration control, and automated cleaning systems. Leading manufacturers continuously innovate, incorporating the latest technology, such as ultrasonic cleaning, to prevent mesh clogging and improve sifting efficiency.

Types of Industrial Flour Sifters

Different types of flour sifters are available depending on production requirements, type of flour, and desired outcome. Here are the primary types used in industrial settings:

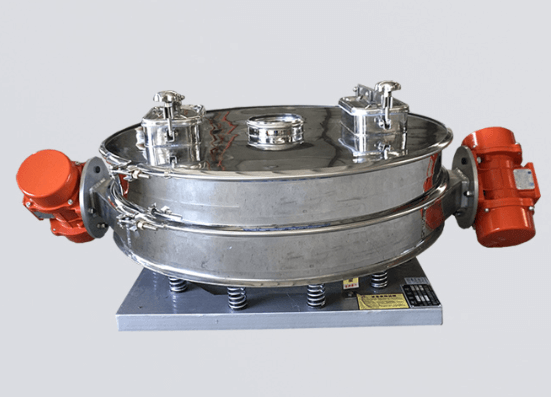

- Vibratory Sifters: Using vibration to separate particles, vibratory sifters are ideal for fine flour with consistent particle sizes. They offer high throughput, making them suitable for large-scale operations.

- Centrifugal Sifters: Centrifugal sifters operate by spinning the flour in a cylindrical chamber. This method is efficient for sifting out fine particles and is suitable for powdery, soft flours often used in baked goods.

- Rotary Sifters: In rotary sifters, flour passes through a rotating mesh screen, which removes unwanted materials. This type is effective for coarser flours and works well with larger production volumes.

- Ultrasonic Sifters: Ultrasonic sifters use sound waves to prevent the flour from clogging the screen, providing efficient sifting without interruptions. These sifters are particularly useful in sifting fine powders.

Each type of sifter has unique advantages, and the right choice depends on specific needs, production volume, and the type of flour being processed.

Key Features to Consider in Industrial Flour Sifters

Selecting the right flour sifter requires careful consideration of several important features:

- Capacity and Throughput: Look for sifters with the right capacity to match production needs. Higher throughput models are essential for large-scale operations to keep up with demand.

- Mesh Screen Quality: The quality and adjustability of the mesh screen directly affect sifting precision. Fine mesh screens produce more refined flour, while coarser screens are better suited to larger particles.

- Ease of Cleaning and Maintenance: For food safety and regulatory compliance, sifters must be easy to clean. Many manufacturers offer sifters with quick-access designs that simplify maintenance.

- Material Durability: Industrial sifters made from stainless steel are more durable and resistant to corrosion. This is especially important in food processing to avoid contamination and ensure longevity.

- Automation and Control: Automated sifters with customizable settings allow operators to adjust speed, vibration intensity, and other parameters to suit different types of flour and production needs.

Choosing a sifter with these features ensures greater control over product quality, reduces downtime, and maximizes productivity.

Top Industrial Flour Sifter Manufacturers

Several leading manufacturers produce reliable, high-quality industrial flour sifters. Here are some of the top providers trusted by businesses in the food processing industry:

i. SWECO

One of the leading names in industrial sifters, SWECO specializes in vibratory sifters and separators. Known for their innovative designs, SWECO sifters offer high efficiency and customizable settings. Their sifters are durable and ideal for applications where precision and reliability are critical.

- Key Products: SWECO offers various vibratory sifters suitable for fine and powdery flours.

- Industries Served: Food and beverage, pharmaceuticals, and chemical processing.

ii. Russell Finex

Russell Finex is another well-known manufacturer that provides high-quality screening and filtration equipment. Their flour sifters are known for ease of use, high performance, and compliance with food-grade standards. Russell Finex also offers ultrasonic sifters for fine, sticky powders that might otherwise clog traditional screens.

- Key Products: Vibratory sifters, ultrasonic sifters, and centrifugal sifters.

- Industries Served: Food processing, pharmaceuticals, and chemical industries.

iii. GEA Group

GEA Group is a global provider of food processing equipment, including high-performance centrifugal and rotary sifters. Their machines are known for robust construction, versatility, and ability to handle large volumes, making them suitable for high-capacity production lines.

- Key Products: GEA specializes in centrifugal sifters for smooth, continuous flour processing.

- Industries Served: Large-scale food processing, dairy, and agricultural sectors.

iv. Kason Corporation

Kason Corporation produces a range of vibratory sifters with a focus on durability and reliability. Their sifters are designed to withstand high-volume production and offer easy maintenance, making them a preferred choice for commercial kitchens and bakeries.

- Key Products: Vibroscreen vibratory sifters, centrifugal sifters.

- Industries Served: Food, chemical, and pharmaceutical industries.

v. BM&M Screening Solutions

BM&M specializes in custom-built screening and sifting solutions tailored to the food processing industry. Their sifters are highly effective in handling various types of flour and offer customizable screen sizes and sifting speeds for flexibility in production.

- Key Products: Custom vibrating sifters with adjustable screen sizes.

- Industries Served: Food processing, agricultural, and industrial manufacturing.

Each of these manufacturers offers unique benefits, from advanced vibration controls to robust, food-safe designs. Businesses can select based on their specific production requirements, desired capacity, and budget.

The Benefits of Choosing Quality Flour Sifter Manufacturers

Working with reputable flour sifter manufacturers provides multiple advantages for businesses:

- Consistent Quality Control: Reputable manufacturers prioritize high-quality materials and production standards, ensuring that each batch meets consistency requirements.

- Enhanced Productivity: High-quality sifters from trusted brands offer reliable performance, minimizing downtime and improving overall efficiency.

- Long-Term Durability: Leading manufacturers produce sifters that are built to last, often offering warranties and support for maintenance.

- Regulatory Compliance: Established manufacturers design sifters to meet industry standards, ensuring compliance with food safety regulations.

Investing in a quality flour sifter also pays off over time as it reduces maintenance needs and provides a greater return on investment.

How to Choose the Right Industrial Flour Sifter Manufacturer

When choosing an industrial flour sifter manufacturer, consider the following criteria to make the best selection for your business needs:

- Industry Reputation: Look for manufacturers with a strong track record of customer satisfaction and reliability in your industry.

- Range of Products: Manufacturers offering multiple sifter types and custom options can better meet diverse production needs.

- Technical Support and Warranty: Choose a manufacturer that provides strong after-sales support, including maintenance assistance and warranties on parts and equipment.

- Flexibility and Customization: Businesses with unique processing requirements may benefit from manufacturers that offer customization options for screen size, automation, and design features.

By evaluating these factors, you can partner with a manufacturer that aligns with your business goals, production demands, and quality standards.

Maintenance Tips for Industrial Flour Sifters

Proper maintenance of flour sifters ensures longevity and consistent performance:

- Routine Cleaning: Clean the mesh and surrounding areas regularly to prevent contamination and maintain food safety standards.

- Inspection of Moving Parts: Periodically inspect all moving parts, especially in vibratory sifters, to ensure no loose bolts or worn-out components.

- Screen Replacement: Replace mesh screens when they show signs of wear or reduced effectiveness to maintain high sifting quality.

- Lubrication: Apply lubrication to moving parts as recommended by the manufacturer to ensure smooth operation and reduce friction.

Adhering to these maintenance practices not only extends the lifespan of your sifter but also ensures compliance with hygiene and safety standards in food production.

Conclusion

Industrial flour sifters are essential for businesses in the food processing industry, helping to maintain product consistency, quality, and safety. Selecting a reliable flour sifter manufacturer is crucial for achieving efficiency, meeting regulatory standards, and minimizing production costs. By understanding the different types of sifters, evaluating key features, and considering top manufacturers, businesses can invest in the ideal sifting equipment that aligns with their production needs.

Leading manufacturers like SWECO, Russell Finex, GEA Group, Kason Corporation, and BM&M Screening Solutions offer advanced, high-quality sifting equipment that enhances productivity and ensures quality control. As food industry demands continue to grow, investing in a dependable industrial flour sifter is a step toward ensuring both operational efficiency and customer satisfaction.